Auto

A hard water softener is an appliance that uses sodium chloride, also known as salt, to treat hard water. … In water softening process the water supply passes through the water softener over resin beds, rows of resin beads perform an ion-exchange.

M.S.

That will definitely increase the value of house more. Working in multiple ways: You are not just free from buying a water softener for your use, but you don’t have to go through the mess of installing these softeners or keeping it maintained initially.

Domestic

They are quite expensive but worth the investment as softened water does offer some significant benefits. … Softened water feels silkier and makes hair softer and easier to manage. the appropriate water softener size for your home, multiply the number of people in your home by the gallons of water they use each day (80 gallons per person is the average). Multiply that number by the grains of hardness in your water to figure out how many grains need to be removed each day.

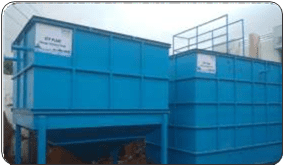

Industrial

Installing a water softener yourself allows you to work on the project at your own pace and without spending extra money on a plumber. If you’re simply replacing an old water softener, this can be done in under an hour. … You may have copper, PVC, CPVC, steel or PEX plumbing.

Specifications:

- Flow Rate: The flow rate of a water softener plant is measured in liters per hour (LPH) or gallons per minute (GPM). The flow rate required for a particular application will depend on the size of the facility and the volume of water needed.

- Resin Capacity: The resin capacity of a water softener plant determines the amount of hardness-causing minerals it can remove before it needs to be regenerated. The resin capacity is measured in cubic feet or liters.

- Regeneration Frequency: The frequency of regeneration is the number of times the resin needs to be regenerated per day or week. This depends on the resin capacity, the level of hardness in the water, and the amount of water being processed.

- Operating Pressure: The operating pressure of a water softener plant should be within a specified range to ensure that the system works efficiently. The operating pressure is typically measured in pounds per square inch (PSI) or bars.

- Salt Consumption: The amount of salt used in the regeneration process is another important specification. The salt consumption will depend on the resin capacity and the level of hardness in the water.

- Control System: The control system of a water softener plant should be user-friendly and easy to operate. It should be able to monitor and control the regeneration process automatically.

- Construction: The water softener plant should be constructed of high-quality materials that are resistant to corrosion and erosion. It should also be designed to handle the specific water quality and flow rate of the application.

- Maintenance: The maintenance requirements of the water softener plant should be minimal, and the plant should be easy to clean and maintain. It should also be designed to allow for easy access to the control system and resin tank.

Reviews

There are no reviews yet.