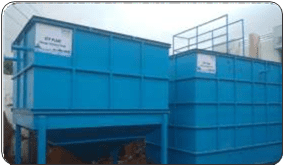

Industrial R.O. plants are typically used in large-scale water treatment applications, such as in the production of purified water for industrial processes or for the treatment of wastewater. These plants can produce a large amount of purified water per day, ranging from several thousand to several million gallons.

Commercial R.O. plants, on the other hand, are used for smaller-scale applications such as in restaurants, hotels, and other commercial establishments. These plants can produce several hundred to several thousand gallons of purified water per day, depending on the size of the plant.

Both industrial and commercial R.O. plants are an effective way to remove impurities from water and produce high-quality purified water for various applications. However, they require regular maintenance and monitoring to ensure optimal performance and longevity of the system.

Specifications:

- Capacity: The capacity of the R.O. plant is measured in terms of liters per hour (LPH) or gallons per minute (GPM). The capacity can range from 100 LPH to several thousand LPH or more.

- Operating pressure: The R.O. plant operates under high pressure, typically between 150 and 250 pounds per square inch (psi).

- Membrane type and size: The type and size of the R.O. membrane used in the plant depend on the quality of the feedwater and the desired quality of the product water. The membranes are typically made of thin-film composite (TFC) material and range in size from 2.5 inches to 8 inches in diameter.

- Pre-treatment: The feedwater is pre-treated to remove impurities such as sediment, chlorine, and other contaminants that could damage the R.O. membrane. Pre-treatment can include multi-media filters, activated carbon filters, and water softeners.

- Post-treatment: After the water has been purified by the R.O. membrane, it may undergo additional treatment to adjust the pH, remove any remaining impurities, and add minerals back into the water.

- Control system: The R.O. plant is typically controlled by an automated system that monitors the pressure, flow rate, and quality of the water and adjusts the operation of the plant accordingly.

- Power supply: The R.O. plant requires a reliable power supply to operate, and the power requirements depend on the size of the plant.

- Installation: The R.O. plant is typically installed on a skid or a frame and requires a dedicated space for installation. It may also require a water storage tank and a pump to supply the feedwater to the plant.

Reviews

There are no reviews yet.